Multi-Fuel Boiler: Advantages of Solid Fuel

Solid fuels are one of the oldest and traditional methods of obtaining energy. As a results, they are still in use today alongside with liquid fuels in many industrial systems, including boilers. This article will focus on the benefits of using solid fuels in boilers and heaters.

What are Solid Fuels?

Any material which provides energy as a result of combustion can be termed as “solid fuel”. Since solid fuels are prone to burn with smoke, they might be prohibited in smoke controlled areas. However, smokeless solutions do exist and can be quite beneficial if used right.

Advantages of Solid Fuels:

- Safe Storage:

Unlike flammable liquid fuels which can start a fire in case of minor sparks or ignition, solid fuels generally require a higher power source for them to burn. As a result, they do not require specifically designed tanks or containers for storage. Switches, light bulbs, plugs and temperature controls all count as ignition sources for liquid fuels but have little to no impact on solid fuels. Hence, the safety features required in solid fuels storage areas are relatively less as compared to liquid fuels. While using solid fuels, you do not need to worry about spillage, friction and pressure build-up with time. All of which, in other fuels, can lead to high risks of explosions and fire.

- Easy Transportation:

Although solid fuels might take up large space, they are generally more stable to transport from one place to another, with minimal safety risks. As a company, you do not require fuel trucks having specialized material to keep the fuel from causing harms. There is no problem of leaks. In case of an accident, there is substantially lower chance of destruction and explosions. Plus, if the solid fuel trucks have any mishap and end up with the material on the roads, the company can retrieve most of it. As a result, solid fuels are still usable in case of spillage, which is not the case with other types of fuels.

Also, solid fuels rarely expand, and if they do, there is little to no risk of them igniting due to friction or small sparks. Hence, the solid fuel containers can be filled to the brim and taken to faraway places.

- Low Cost:

Solid fuels are marginally cheaper than other types of fuels. With the world moving towards green solutions, most of the solid fuels utilized are waste or renewable energy sources. Such sources are readily available and require minimum investment to acquire. On the other hand, liquid fuels are present underground and their acquirement require drilling, pumping, pipelines and costly safety equipment, leading to raised prices. In case of solid fuel boilers, industries can not only clean up the waste from landfills, for example, manure and garbage, but can also utilize the waste produce in their own plants as an energy source.

Examples of such green fuels involve rice husks, corn cobs, cassava waste, briquettes, RDF and wood waste. Most of these materials have low moisture and high LCV, meaning easy and efficient combustions.

- Fewer Odors:

The major problem the general public has with the industries is the environmental impacts they product, and one of them is the odor. Fuels other than solids have a sharp smell associated with them, making the surroundings areas unpleasant and stinky; for example, oil distillation can lead to bad smells. If the neighbors raise complains, you might get orders to shut down or relocate.

- High LCV at low costs:

Calorific value is defined as the amount of heat produced when a fuel is combusted. It is the heat per kilogram of solid or liquid. The LCV (Lower Calorific Value) of some solid substances are quite high, while they are low priced. For example, wooden pellets (dense crushed sawdust, forest residue and other waste) are high calorific fuels, along with rice husk. The capital investment for obtaining these substances is non-existent as compared to other processes. However, due to their high LCV and low moisture content, they produce higher output/ profits for very small inputs.

- Does not thicken with climate

Liquid fuels, for example, diesel, carries paraffin. At temperatures around 0 degrees Celsius, it begins to solidify, making diesel thick. It can clog up pipes and tank filters at temperatures lower than 0 degree Celsius, leading to a process called “gelling”. Similarly, other types of fuels can also become thick in cold climates, causing maintenance problems. Solid fuels are free of such temperature impacts. They may expand or shrink a little, however, they do not require special treatment or extra maintenance in extreme climates.

- Flexible Boilers:

With the advancement in technology, most of the solid fuel boilers now come with the multi-fuel technology. That means one can easily shift them from solid fuel to liquid and gas fuels. Sometimes, it also means that they can utilize different types of solid fuels.

Multi-fuel boilers helps industries to use the cheapest, most efficient fuel available in the market, and easily jump from one fuel to another when the supplies dry up.

Find the Best Solid Fuel Boilers Today!

GETABEC provides the best plans for burning biomass or Solid Recovered Fuel. Our company believes in green and clean energy, which is why we have created Biomass Boilers that can work with the solid fuel of your choice. You can choose from both urban and natural waste, including oat hulls, rice hulls, sunflower hulls, coffee grounds and much more!

Contact us today for more information on our highly efficient, reliable and flexible biomass boiler today!

Use of Steam

- Food

- Beverage

- Automotive

- Pharmaceutical & Chemical

- Textile & Fabric

- Petrochemical & Power Plant

- Packaging

- Hotel & Hospital

- Construction Materials

More Topics to Read !

Our Blogs

- How do steam boiler work ?

- Advantages of solid fuel !

- Classification of steam boilers

- How does HRSG work ?

- Thermal oil heating system design

- Key considerations for choosing a good steam boiler.

Fire tube boiler projects

Industry : Food

Location:Nakhonratchasima (Thailand)

Boiler type : HDO 3200/13

Boiler model : Output 3.2 t/hr, 11 bar (a)

Steam temperature : 188 °C

Industry : Paper

Location : Bangbon Bangkok (Thailand)

Boiler type : HDO 3200/13

Boiler model : Output 3.2 t/hr, 11 bar (a)

Steam temperature : 188 °

Industry : Packaging

Location : Rayong

Boiler type : 2xHDO-10000/16

Fuel type : CKB

Capacity : 10 ton/hr.

Industry : Packaging

Location : Khon Kaen

Boiler type : 1xHDO-6000/16

Fuel type : CKB

Boiler model : 6 ton/hr.

Industry : Beverage

Location:Chai Nat (Thailand)

Boiler type : 2xHDO-15000/10

Fuel type : Heavy oil, Biogas

Boiler model : 15 ton/hr.

Industry : Waste water treatment

Location : Chai Nat

Boiler type : 1xHDO-15000/10

Fuel type : LPG, Vinasse

Boiler model : 15 ton/hr.

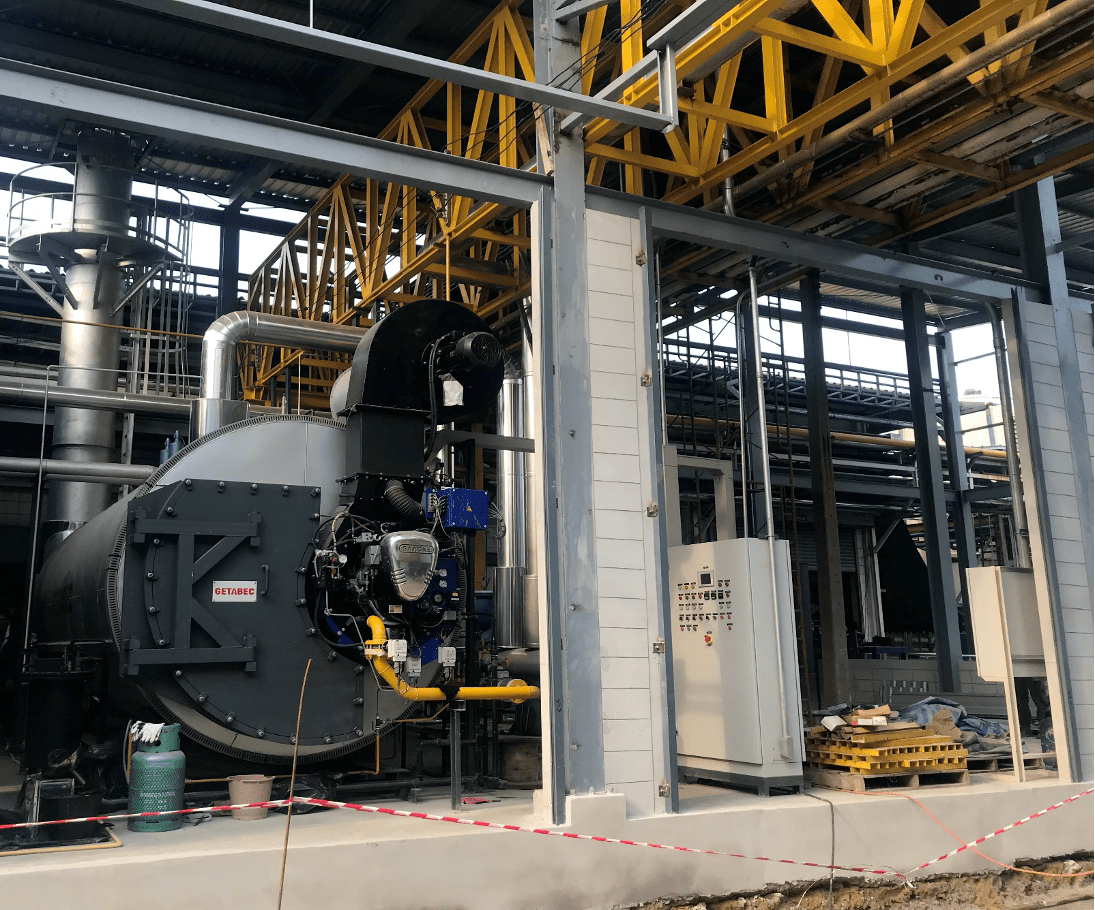

Industry : Tyres

Location : Rayong

Boiler type : 2xHDO 12000/24

Fuel type : Natural gas

Boiler model : 12 ton/hr.

Industry : Packaging

Location : Samut Prakan

Boiler type : 1xHDO-10000/10

Fuel type : Heavy oil, LPG

Boiler model : 10 ton/hr.

Project Mckey Food

Location : Chonburi (Thailand)

Boiler type : HDO 3200/10

Boiler model : Output 3.2 t/hr 8 bar (a)

Steam temperature : 175 °C

Previous

Next

Get In Touch!

LET’S START WORK

TOGETHER

Please feel free to contact us. We will get back to you with 2-3 business days. Or just call us now.

- +66 236 604 007

- [email protected]

- 335/7 Srinakarin Road, Nongbon, Prawet Bangkok 10250, Thailand