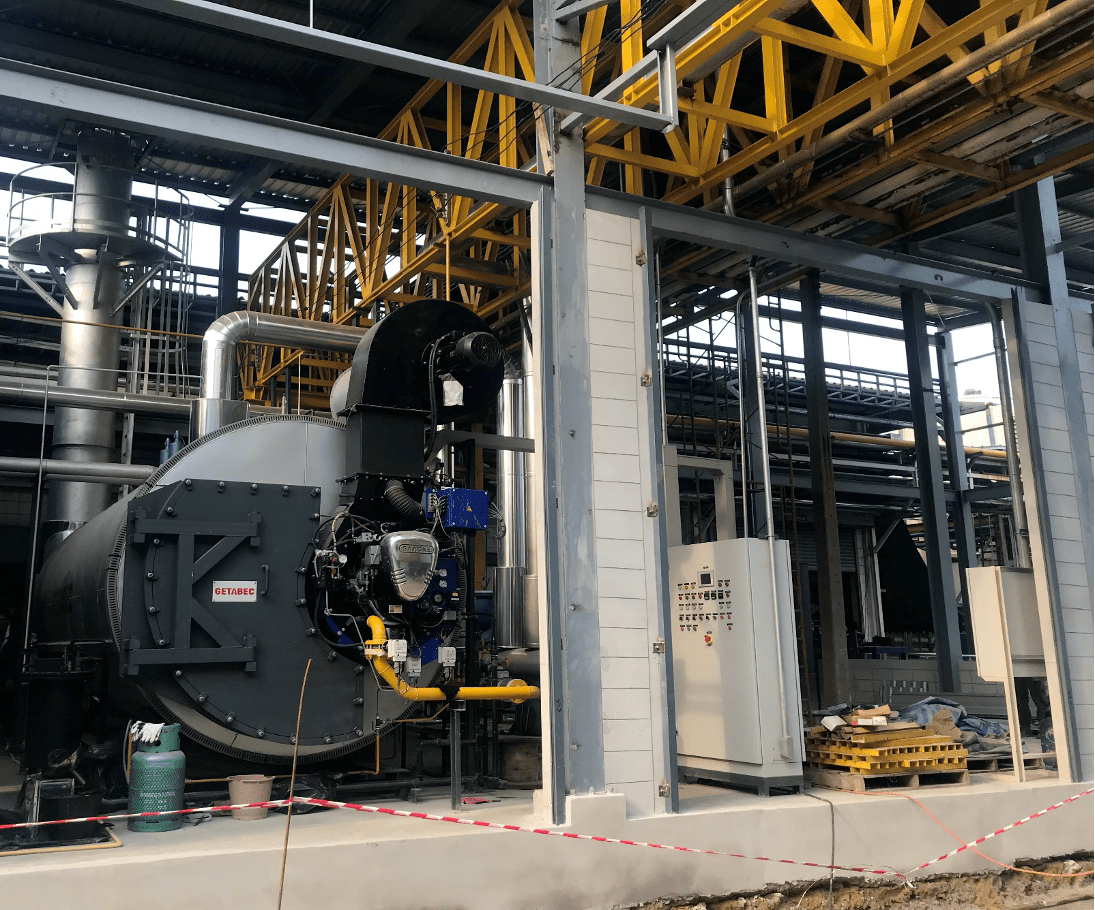

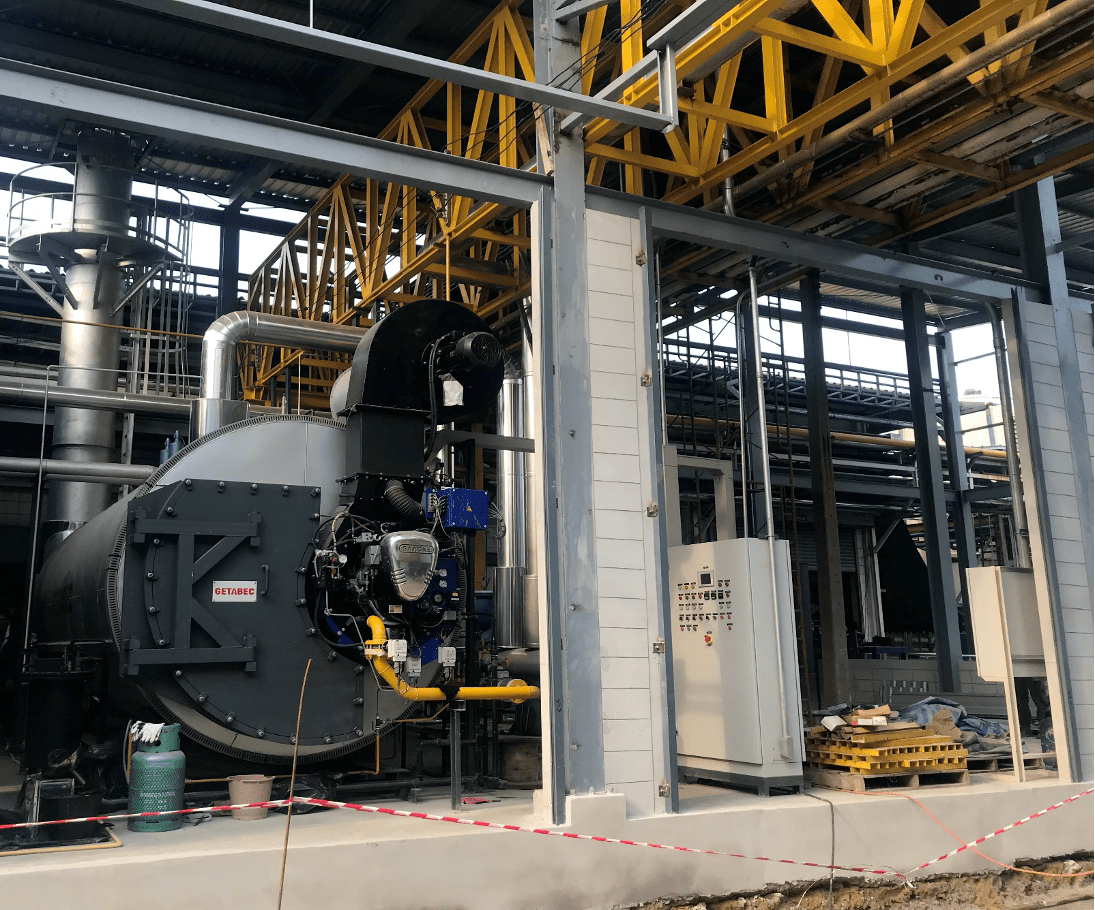

Double Flame Tube Design, Model HDO-D

Performance range up to 50 t/h

There are two primary fire tube boiler designs: “Wetback” and “Dryback.” Wetback design has water around the rear reversal chamber, whereas the dryback design has refractory lining the rear end plate.

We have ASME certificate for produce boiler & pressure vessel.

Water heated to the boiling point vaporizes into steam known as the “Saturated” steam. When this water is further heated above the boiling point without any change in pressure, dry steam known as “superheated” steam is generated.

Every time hot flue gases pass through a set of smoke tubes or furnace tubes before making a turn, a “pass” is said to be made. In our three-pass design, the gases first pass through the furnace tube –this is the first pass. After that, they pass through the smoke tubes –this is the second pass. And in the end, the gasses take a turn and pass through another set of smoke tubes –this is the third pass. This design ensures maximized heat transfer.

A wetback fire tube boiler design:

Quick response to load changes

Requires less maintenance due to the absence of refractory

คุ้กกี้และเทคโนโลยีติดตามอื่นๆ

คุกกี้คืออะไร? คุกกี้คือสิ่งที่ใช้กันอย่างแพร่หลายในอินเทอร์เน็ต โดยคุกกี้คือไฟล์ข้อความขนาดเล็กที่ถูกจัดเก็บไว้ในเบราเซอร์ของท่าน ซึ่งประกอบไปด้วยข้อมูลพื้นฐานเกี่ยวกับการใช้อินเทอร์เน็ตของท่าน อาทิ รายละเอียดการเข้าสู่ระบบ และ ประวัติการท่องเว็บของท่าน คุกกี้สามารถจำแนกออกได้ในแง่ของระยะเวลา และบุคคลผู้จัดเก็บ

เมื่อท่านเข้าเยี่ยมเว็บไซต์ Getabec จะทำการบันทึกการเข้าเยี่ยมของท่านเท่านั้นและจะไม่ทำการเก็บรวบรวมข้อมูลระบุความเป็นตัวตนใด ๆ (คือ ข้อมูลที่เกี่ยวกับท่านและระบุตัวตนของท่าน) จากท่าน เว้นแต่จะระบุไว้เป็นอย่างอื่น คุ้กกี้และเทคโนโลยีติดตามอื่นๆที่ใช้ (หากมี) ในส่วนของเว็บไซต์ของ Getabec จะไม่นำไปใช้ในการเก็บรวบรวมข้อมูลความเป็นบุคคล เพื่อแจ้งให้ทราบ คุ้กกี้เป็นไฟล์คอมพิวเตอร์ขนาดเล็กที่จัดเก็บในการท่องเว็บของคอมพิวเตอร์เพื่อวัตถุประสงค์ในการกำหนดค่าการเก็บข้อมูลและวิเคราะห์ความเคยชินในการเข้าดูของการท่องเว็บ โดยที่สามารถช่วยให้ท่านประหยัดเวลาจากการลงทะเบียนอีกครั้ง เมื่อได้มีการกลับมาเยี่ยมที่เว็บไซต์อีกครั้งและมักใช้ในการติดตามความต้องการของท่านในหัวข้อที่เกี่ยวข้องกับเว็บไซต์ ท่านอาจปฏิเสธที่จะยอมรับคุกกี้ (โดยการแก้ไขตัวเลือกอินเทอร์เน็ตที่เกี่ยวข้อง หรือเรียกดูข้อมูลการตั้งค่าของระบบคอมพิวเตอร์ของท่าน) แต่หากท่านทำเช่นนั้น ท่านอาจจะไม่สามารถที่จะใช้ หรือเปิดใช้งานฟังก์ชั่นบางอย่างในเว็บไซต์ของ Getabecได้ เพื่อการให้บริการท่านได้รวดเร็วขึ้นและมีคุณภาพที่ดีกว่า เราได้ใช้เทคโนโลยี "คุ้กกี้" และยังอนุญาตให้บุคคลที่สามใช้คุ้กกี้และเทคโนโลยีติดตามอื่นๆบนไซต์ของเราด้วย เราทำงานร่วมกับบุคคลที่สามที่วางคุ้กกี้และเทคโนโลยีติดตามอื่นๆบนไซต์ของเราเพื่อให้บริการ โดยรวมไปถึง:

การวิเคราะห์/การวัด: Getabecใช้คุ้กกี้และเทคโนโลยีติดตามอื่นๆวิเคราะห์จากบุคคลที่สามเพื่อรับทราบข้อมูลเชิงลึกว่าผู้เยี่ยมชมใช้งานไซต์ของ Getabec อย่างไร เพื่อดูว่าสิ่งใดที่ใช้การได้และไม่ได้ เพื่อเพิ่มประสิทธิภาพและปรับปรุงเว็บไซต์ของ Getabecและเพื่อรับรองว่า Getabecยังคงเป็นที่น่าสนใจและยังมีความเกี่ยวเนื่อง ข้อมูลที่ Getabec รวบรวมโดยรวมถึงหน้าเว็บที่ท่านได้ดู หน้าที่อ้างอิง/สุดท้ายจากหน้าที่ท่านได้เข้าและออก แพลตฟอร์มและระบบปฏิบัติการที่ท่านได้ใช้ วันที่และเวลาที่ประทับข้อมูล และรายละเอียดต่าง ๆ เช่น จำนวนคลิกที่ท่านทำบนหน้าที่กำหนด การเคลื่อนไหวของเมาส์ของท่านและกิจกรรมการเลื่อน การค้นหาคำที่ท่านใช้และข้อความที่ท่านพิมพ์ในขณะที่ใช้ไซต์ของ Getabec ยังใช้คุ้กกี้วิเคราะห์เป็นส่วนหนึ่งของแคมเปญโฆษณาออนไลน์ของ Getabecเพื่อที่จะเรียนรู้วิธีที่ผู้ใช้โต้ตอบกับเว็บไซต์ของเราภายหลังจากที่พวกเขาได้รับการแสดงที่โฆษณาออนไลน์ ซึ่งอาจรวมถึงการโฆษณาในเว็บไซต์ของบุคคลที่สาม

วิธีการจัดการความยินยอมของท่าน

ท่านสามารถยอมรับหรือปฏิเสธการใช้คุกกี้ได้ทุกเวลา โดยการจัดการและ/หรือปิดใช้งานคุกกี้ทั้งหมดหรือบางส่วนจากการตั้งค่าเบราเซอร์ของ ท่านอย่างไรก็ตาม โดยการทำเช่นนั้น ท่านอาจจะไม่สามารถใช้งานเว็บไซต์ของเราได้อย่างมีประสิทธิภาพสูงสุดโดยปกติแล้ว ท่านสามารถตรวจสอบการตั้งค่าคุกกี้ได้ที่เมนูการตั้งค่าจากเบราเซอร์ของท่าน ดังนี้:

คุกกี้พื้นฐานที่จำเป็น

คุกกี้พื้นฐานที่จำเป็น เพื่อช่วยให้การทำงานหลักของเว็บไซต์ใช้งานได้

รวมถึงการเข้าถึงพื้นที่ที่ปลอดภัยต่างๆ ของเว็บไซต์ หากไม่มีคุกกี้นี้เว็บไซต์จะไม่สามารถทำงานได้อย่างเหมาะสม และจะใช้งานได้โดยการตั้งค่าเริ่มต้น โดยไม่สามารถปิดการใช้งานได้

คุกกี้ในส่วนวิเคราะห์

คุกกี้ในส่วนวิเคราะห์ จะช่วยให้เว็บไซต์เข้าใจรูปแบบการใช้งานของผู้เข้าชมและจะช่วยปรับปรุงประสบการณ์การใช้งาน โดยการเก็บรวบรวมข้อมูลและรายงานผลการใช้งานของผู้ใช้งาน

คุกกี้ในส่วนการตลาด

คุกกี้ในส่วนการตลาด ใช้เพื่อติดตามพฤติกรรมผู้เข้าชมเว็บไซต์เพื่อแสดงโฆษณาที่เหมาะสมสำหรับผู้ใช้งานแต่ละรายและเพื่อเพิ่มประสิทธิผลการโฆษณาสำหรับผู้เผยแพร่และผู้โฆษณาสำหรับบุคคลที่สาม