A steam boiler is a device generally consisting of a large closed chamber in which heat is applied to the water in order to create steam. A steam boiler has various components. These components ensure that the required properties of the produced steam are achieved. In this post, we plan to discuss the question: how do steam boilers work and the different aspects that need to be taken care of for their proper functioning.

Burning of the fuel:

Steam boilers work by burning the fuel in the combustion chamber. Air mixed with fuel is necessary for this process. This is because air is a mixture of several gases, including Oxygen, which is a key component required for the process of combustion. Sufficient air is provided to the fuel so that complete combustion can take place. One of the identification characteristics of Complete Combustion is the product left behind. A Complete Combustion process produces Carbon dioxide and water as its by-products. If the air mixed with fuel is less than the required amount, incomplete combustion will take place. The combustion chamber is a crucial part of the boiler as it is directly related to the efficiency, operational costs, and overall safety of the boiler.

Heat transfer between the water and fuel:

To heat the water, the burnt fuel is moved through different tubes across the water to increase its temperature. The boiler tubes are made to have multiple passes through the water, and it keeps raising the water’s temperature with every pass (heat exchangers). Since the entire chamber is not at a uniform temperature, therefore, temperature across the water varies as well, leading to a gradual change into steam. By using multiple passes, maximum heat transfer can occur between the fuel and water, which is why most of the water can be converted to steam, improving the overall efficiency of the steam boiler.

Build-up of high pressure:

Water is kept in a closed chamber in the steam boilers, usually cylindrical in shape, where it is heated to form steam. Since the container is closed, there is an immense pressure build-up in the chamber. The steam then moves through pipes to the required location. Steam from boilers has numerous uses. It is used in various thermal power plants to generate electricity by rotating the turbines. Industrial boilers are used in cooking food. Furthermore, steam from boilers is also used in HVAC (Heating, Ventilation, and Air Conditioning) systems to keep the temperature warm during winters. It is used in hotels to produce hot water and in chemicals to clean containers as well.

Removal of exhaust gases:

The gases produced during the combustion process, that is, Carbon dioxide, Carbon monoxide, and water vapours/steam (water vaporizes due to release of very large amounts of energy during the combustion process), need to be removed from the boiler chamber, and so, through exhaust openings, such as chimneys, these gases are released in the outside environment.

Other factors:

For the proper boiler functioning, a few factors must be taken into account. These factors are:

Complete Combustion of the fuel:

The fuel needs to go through complete combustion under the presence of ample air. If the air present is insufficient, incomplete combustion takes place whose products are Carbon monoxide, a toxic gas, as well as Carbon soot is produced as a result. Carbon monoxide is extremely dangerous for humans, while Carbon deposits can decrease the overall efficiency of the steam boiler. Incomplete combustion means that the proportion of the fuel and air used isn’t correct and so, whether it’s the fuel or the air, using either in excess is going to cost more economically. The gases produced during incomplete combustion also decrease the lifetime of the stack (chimneys etc.) as they erode away the chimney lining, and after that, target its inside layers as well, reducing the structural integrity of the stack and its effectiveness in directing the gases outside. Furthermore, the Carbon (black soot) produced due to incomplete combustion can cause black smoke to come out of the stack. This can cause irritation in the eyes of the people in the community and they can file a law suit against you. It can also cause environmental control authorities to take legal actions against you for causing pollution.

Quality of Feedwater:

The water that will be converted to steam needs to have certain characteristics. It needs to be purified, which can be done through a different filtration process, and the pH needs to be adjusted as well. If the feedwater isn’t treated to have the required properties, it can have a disastrous effect on the steam boiler. When the water is heated and boiled into steam, the salts present in it will be left behind and will start to deposit in the boiler chamber, which will then decrease the efficiency of the boiler. Furthermore, these minerals in water (and sometimes even the leftovers) can react with the walls of the chamber and corrode it, leading to increased maintenance costs. This problem can be taken care of by using boiler blowdown which is the intentional removal of water so that impurities are not collected at a place.

Cylindrical Chambers:

Steam boilers need to withstand extremely high pressure built up inside of them as more and more water is boiled into steam. A cylindrically shaped chamber is selected for this purpose as it has the least stress concentration locations as compared to other shapes. The stress concentrations are the locations that, if subjected to high pressure or load, can cause cracks or damage and lead to failures. Most stress concentrations are present at locations with sharp edges and corners. That’s why, Cube, cuboid, and similar shapes are not suitable for usage in a steam boiler, and a cylindrical chamber, having no corners or edges, is preferred in steam boiler systems.

Steam boilers can have several different types, but the basic principle and working are essentially the same, that is, to convert water into steam by heating the water and then use the steam from the boilers for further applications. Since, boilers can have an average efficiency of 88%, they use steam which is a clean way to transfer energy. Due to this and the fact that they have numerous applications in hundreds of industries, their global market is expected to grow to US$ 21.63 billion by the year 2023.

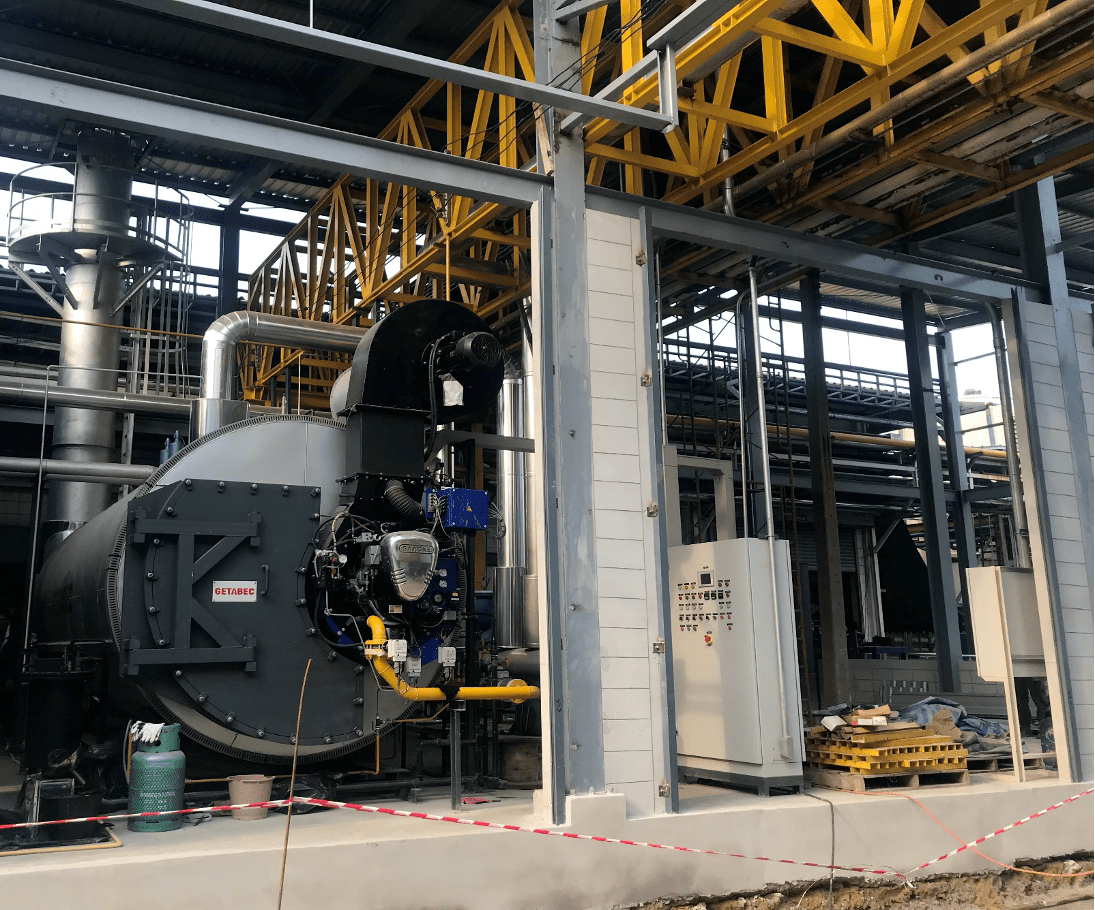

If you are looking for an internationally certified leading boiler company in Asia, you are at the right place! Contact GETABEC for all kinds of boilers solutions. As an engineering group, we provide different technologies, such as innovative boiler system technology, and perfectly coordinated components, along with an intelligent control system incorporated with touchscreens for the ease of interfacing for your boilers.

Contact us at our telephone number, (66) 02-366 0400-7, or at our email, [email protected], and get your required boilers manufactured from our internationally certified workshops.

Visit our website at https://www.getabecboiler.com/ for more details.

Reference: