Numerous industrial and commercial processes use steam for various purposes. But boiling water to form steam, especially at industrial and commercial scales, requires a lot of energy input and thus, can be expensive. The energy needed is gotten by burning fuels in large quantities, and the combustion process produces flue gases as well. These gases contain a large part of the combustion energy, which is then wasted as they are usually drawn out from the combustion chambers. So, how can we utilize this energy before the flue gases are removed from the process? Read on to know how exactly it’s done!

What is HRSG?

HRSG stands for Heat Recovery Steam Generator. As its name suggests, HRSG is a heat exchanger that ‘recovers’ the heat that is then used to generate steam. This heat is recovered from those flue gases that are a result of the burning of the fuels. HRSG can be used in many different ways, such as after Gas Turbines. Therefore, by exploiting the energy from the exhaust gases that were going to be wasted, the overall efficiency of the whole system with a heat recovery steam generator can be improved up to 75 – 85%. Heat Recovery Steam Generators can be of two types: horizontal and vertical. In a horizontal HRSG, the direction of the flue gases is horizontal while it is vertical for the vertical type. The type is decided based on the location where the HRSG will be installed, such as if the exhaust gases are exited through a vertical chimney, the vertical HRSG can be used there.

Now that you know HRSG is, let us tell you how does it work:

HRSG Working Principle:

In a Heat Recovery Steam Generator, the feedwater enters from one side, and the hot flue gases enter from the opposite one and usually pass through the water tubes perpendicularly. To have efficient heat transfer, HRSG has three main parts. Some heat is absorbed by the water/steam in the tubes in each part to attain some desired temperature and state. Those states are as follows:

- Economizer:

The economizer is at the location from where the cold feedwater will enter. This part is the farthest away from the entrance of the exhaust gases, and so, the temperature of the water is the lowest. The economizer is usually a multiple-pass heat exchanger with the hot gases flowing from one direction and passing through multiple water tubes. This part is to pre-heat the water so before it goes to the other parts.

- Evaporator:

The water already has absorbed some heat in the economizer and has its temperature higher than the entrance. Hence, when it enters the evaporator, sufficient heat is transferred from the exhaust gases, which raises the temperature well enough for the water to boil and turn into steam. Similar to the economizer, there are usually multiple tubes through which the water flows while the gases move through the superheater to the economizer in a single pass.

- Superheater

Although the water has been converted into steam in the evaporator, the steam is still in the saturated state. This means that it still has some moisture content present in it which, if not removed, can cause damage to the surfaces it will come into contact with by the mechanisms of erosion and corrosion. For this reason, the saturated steam produced in the evaporator is then passed through a superheater. This part of the Heat Recovery Steam Generator is the closest to the entrance of the hot flue gases, and the gases are at the highest temperature there. Therefore, the steam enters the superheated (or the dry) state due to enough heat transfer from the exhaust gases to the steam and has no moisture left.

The superheated steam is then sent to wherever its applications are needed, like a gas turbine to generate electricity by rotating it or a simple industrial kitchen to cook food. This way, the exhaust gases that were going to be wasted provide steam that can be used for multiple purposes, increasing the system’s efficiency as well as saving cost for converting more water into steam.

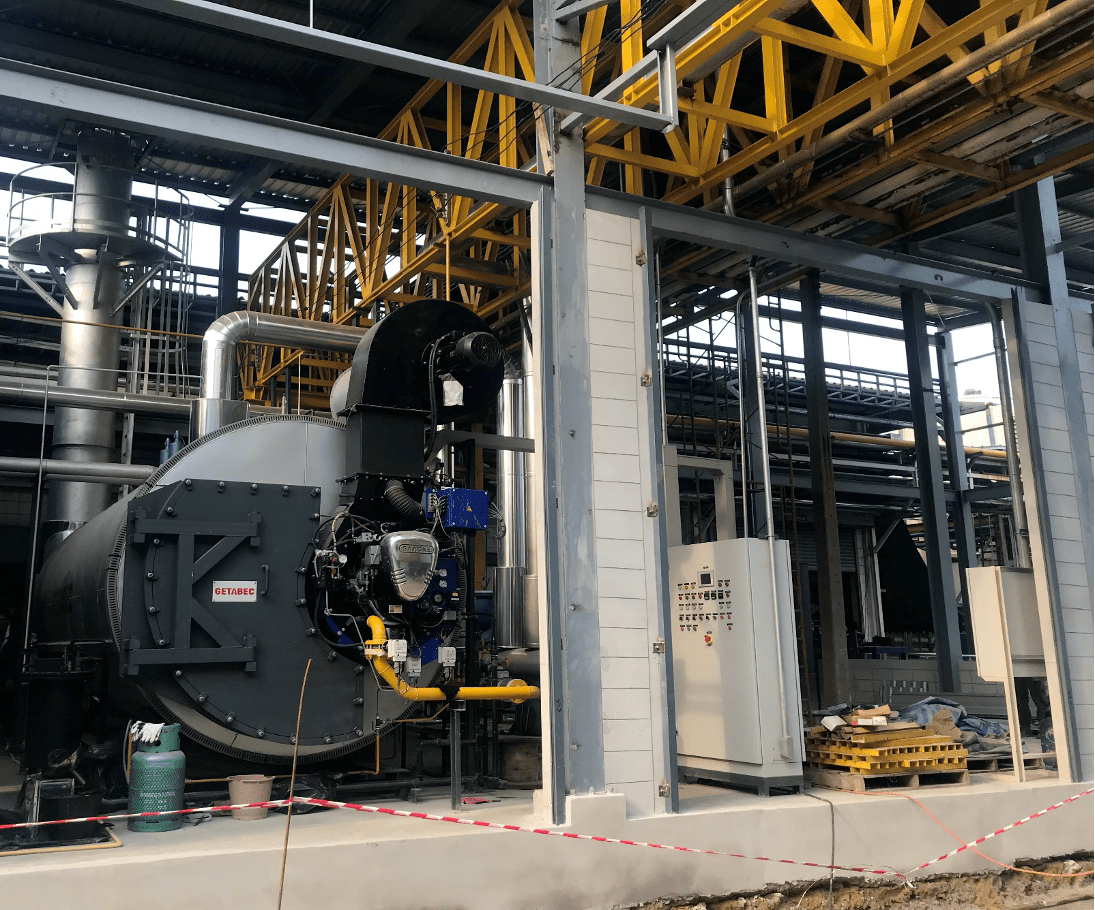

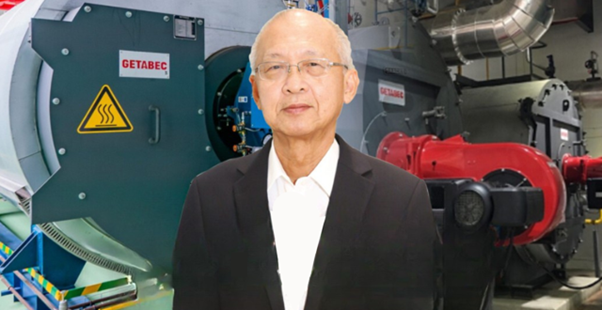

Are you looking to take advantage of the benefits provided by the Heat Recovery Steam Generators yourself? You are at the right place! We, Getabec Public Company, are highly qualified and internationally certified manufacturers for whole systems related to HRSG. We are the biggest steam boiler manufacturers in Thailand and one of Asia’s leading boilers and pressure vessel manufacturers. Whether you need an HRSG after thermal oil heaters or after gas generators, let us know your requirements, and we will provide you with high-performance solutions from a complete system supplier and a well-coordinated system that will be intelligently controlled.Reach out to us here for your HRSG needs!