Steam boilers play an essential role in many different industries, such as power generation and commercial hotels. Their primary function is to generate steam from water, and although it may seem very simple, there are a lot of components involved in a steam boiler to perform this task effectively and efficiently. In this post, we will tell you about the major components of a steam boiler and the role they play in the steam boiler system:

Here are the major boiler components that are necessary for the proper functioning of a steam boiler

- Burner: Burner, as its name suggests, is used to burn fuel to produce heat. Fuel is injected from the fuel inlet, and the air is mixed with it inside the burner. The fuel is ignited, and the combustion reaction between the fuel and the Oxygen from the air produces the heat required to convert the water into steam.

- Combustion Chamber: The combustion reaction takes place inside a chamber known as the combustion chamber. This chamber encloses the burner and keeps the heat from the reaction inside of it, protecting the people outside from the extreme temperature.

- Aquastats: Aquastats measure the water temperature in the boiler and signal the boiler to start or stop accordingly. (Normally for once-through boiler)

- Heat Exchanger: The heat exchanger acts as the path of heat transfer between the burner and the water. This way, the water is heated without coming directly into contact with the burner and fuel. It is because some gases are released as a product of the combustion reaction, which can mix with the water, making it hard to boil and can even release some hazardous products by further reacting with the water.

- Steam lines: There are two major steam lines: the supply lines and the return lines. These are pipes that move the steam to and from different regions in the steam boiler system. The supply lines take the steam generated from the boiler to the areas required, such as for making hot water in hotels. On the other hand, the return line brings back the cooled steam, which can even turn back into the liquid phase after losing its heat energy to the required area, and the cooled steam/water is heated back again in the boiler.

- Condensate pumps: In a steam boiler, the condensate pumps push the condensate water that was converted from steam after its heat energy was utilized at the required place and help it reach back to the boiler so that it can be reheated to generate steam.

- Exhaust Stack: The exhaust stack is used to remove the flue gases that are produced due to the combustion reaction between the air and fuel in the combustion chamber. The flue gases can contain dangerous gases, such as the oxides of Nitrogen and Carbon monoxide, and they can harm the workers and other people in the boiler facility. Therefore, these gases exit the steam boiler system through the exhaust stack.

- Valves: Valves are used to allow or restrict the flow of fluids. There are various valves used in a steam boiler. Backflow valves allow the flow of fluids, that is, steam and water in our case, in only one direction. Safety pressure valves are used to allow excess gas/steam to be removed from the boiler system to reduce the pressure inside of it in case the pressure has risen above the set values. The shut-off valve stops the flow of fuel to the burner if there is some emergency.

- Deaerator: Deaerators are used to remove the dissolved gases from the boiler feedwater. This is done so that the water, when coming into contact with any surface inside the steam boiler system, will not damage that surface by mechanisms like corrosion.

Here were the major components used in a steam boiler. All of these components operate to generate steam but also keeping the boiler system safe from any damage.

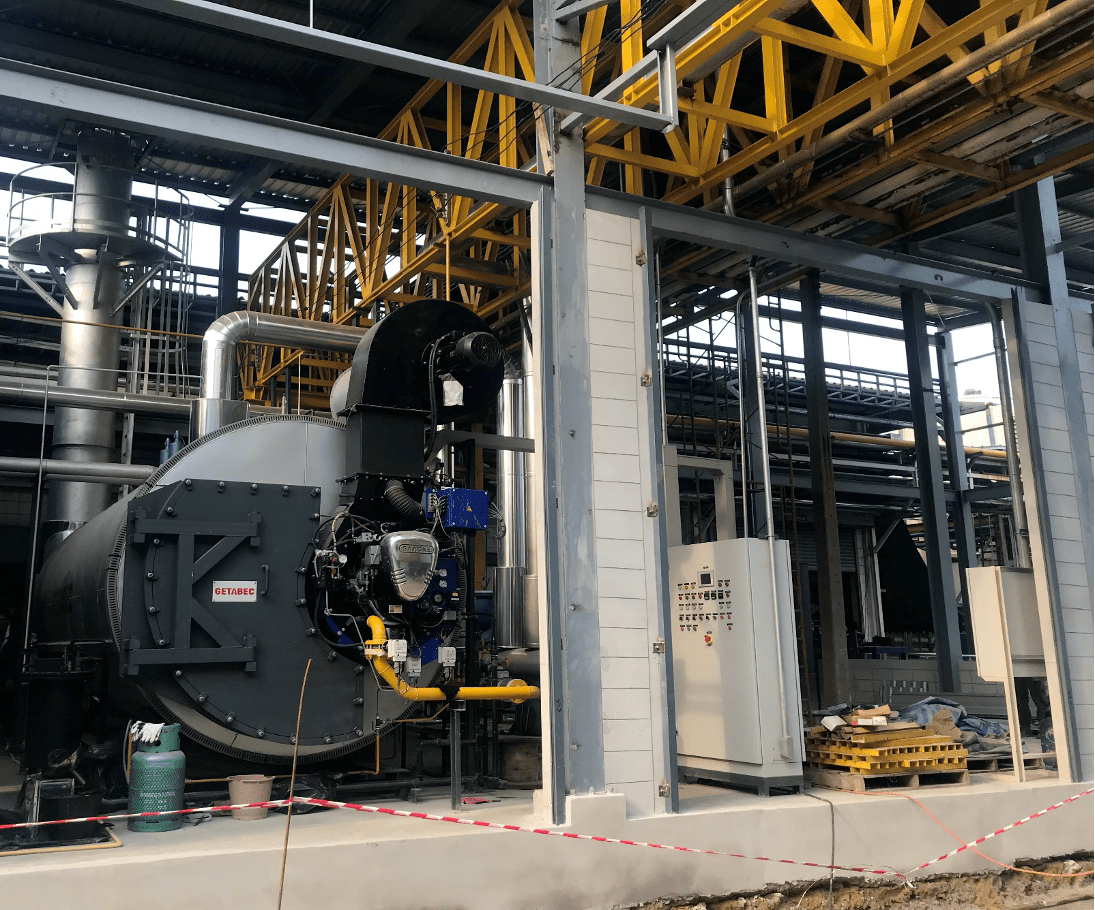

Steam Boilers from GETABEC:

We, GETABEC, are one of the leading boiler manufacturers in Asia. We have internationally certified workshops, and we manufacture boilers under the license of SCHNEIDER-KESSEL Berlin for Fire-Tube Boilers, Eckrohrkessel (ERK) Berlin for Water Tube and Waste Heat Boilers. We have a professional

team that provides a range of services for your boiler, including installation, engineering, and even spare parts. Contact us for all of your boiler needs and leave it up to us to get everything done for you!