With the boiler industry technology growing ever so much in recent years, 3-pass boilers have become advent increasingly. In essence, any type of boiler can be a 3-pass boiler if we take care of specific design considerations. However, the fire tube/ smoke tube 3-pass boilers are seen most commonly in the industries due to their ability to handle steam fluctuations and changing output demands.

What is a 3-Pass Boiler?

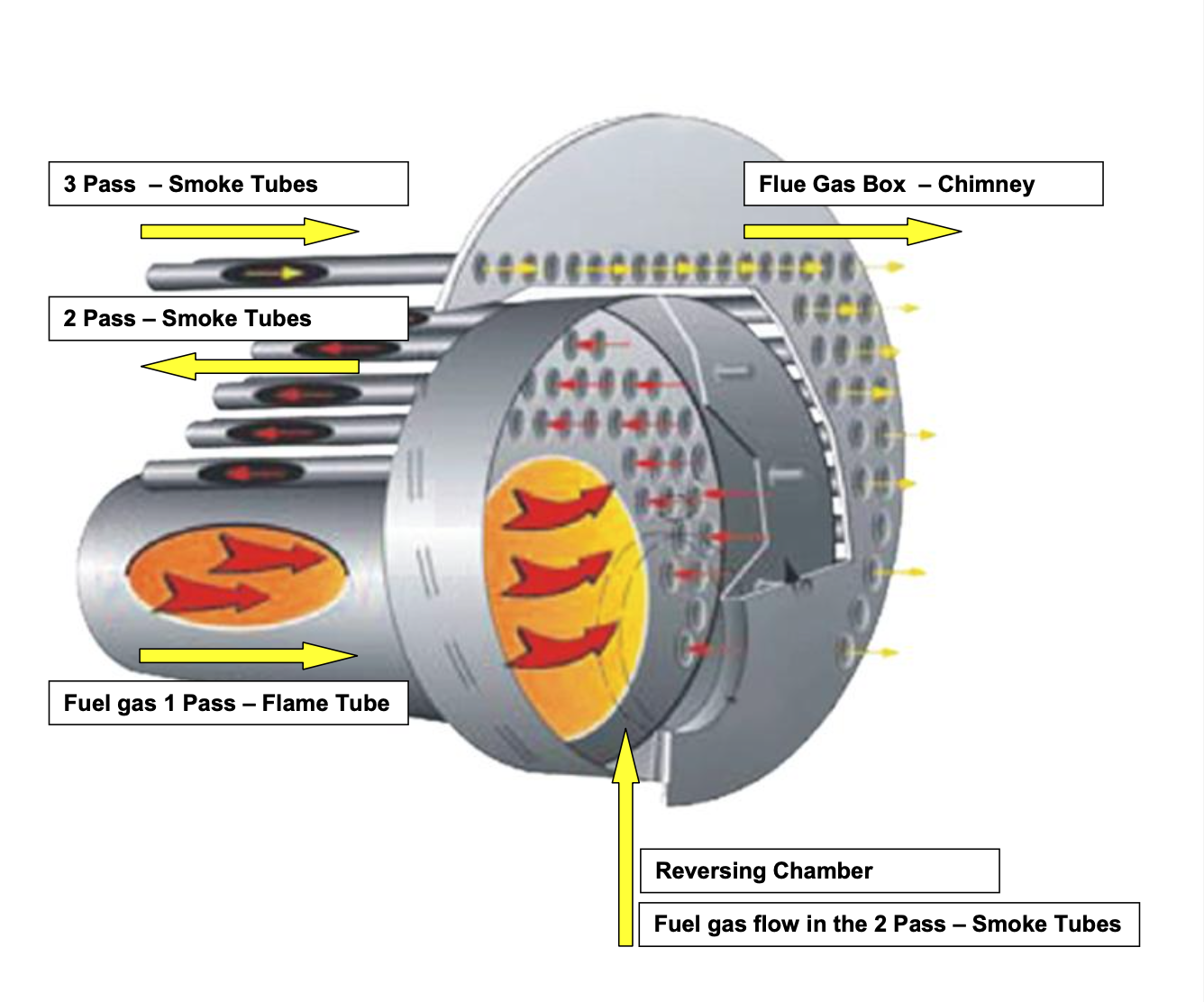

In order to provide a formal definition, a 3-Pass Boiler is any boiler in which the flue-gases (exhaust gases) traverse through the shell back and forth three times before leaving the boiler system through the chimney. Each time exhaust gases cover the entire length of the inner shell of the boiler, we call it a “pass.” This way, a design that allows gases to go through the boiler three times is known as the “3-Pass Boiler.” To explain the exact working and configuration of a 3-Pass Boiler, let us take an example of a fire tube boiler.

Pressure Vessel: A fire-tube boiler consists of a shell/ pressure vessel mounted on some supports. The generation of steam occurs inside this pressure vessel, which is, in most cases, lined on the outside with a thick insulating cover. The purpose of the cover is to prevent the heat from escaping, which can lead to heat loss and, consequently, inefficient boiler operation.

Burner and the Furnace: A burner (fed with air, fuel and provided with ignition) is responsible for the combustion process inside the boiler. In most cases, the combustion takes place inside a corrugated (a series of grooves running across the structure) or non-corrugated cylindrical furnace.

Reversal Chambers and Smoke Tubes: Once the combustion occurs, exhaust gases get thrust towards the exit end of the boiler. If we end our process here, we get a single tube boiler. However, our requirement is a 3-pass boiler. So, we need the flue-gases to take a turn and pass through the boiler again. In order to achieve this process, we have reversal chambers on both ends. There are two reversal chambers in a boiler, namely:

Rear Reversal Chamber –present away from the burner, towards the exit end of the boiler. The rear reversal chamber carries holes on one side (the shell side) and is completely blocked from the other side. Smoke tubes mounted in these holes carry the flue gases back to the front end of the boiler.

Front Reversal Chamber –Present on the burner side, towards the entry end of the boiler. The front reversal chamber, has the same set of holes and another set of smoke tubes mounted on it. The gases again take a turn from the front end, traverse through the second set of smoke tubes and into the smokebox at the rear end of the boiler. From the smokebox, the gases find a chimney and escape from the boiler system.

Why the hot flue-gases are traversing back and forth through the boiler system?

The shell of the boiler carries water in which the smoke tubes are submerged. The flue gases have an extremely high temperature as compared to the water, which instigates thermal conduction. During the first pass, almost 65% of the heat gets transferred to the water. As a result, the flue gases are much cooler when traversing through the smoke tube. Around 25% of the thermal energy transfers to the water during the second and 10% during the third pass. This thermal conduction causes the water to heat above the boiling point and convert into steam. Normally, this steam accumulates in the upper part of the shell above the smoke tubes until the desired pressure or temperature is achieved.

An Important Consideration:

It is crucial that the water level in the shell remains such that the smoke tubes remain submerged completely at all times. Reduced water levels can cause fractures in the smoke tubes, leading to the failure of the entire boiler system. It can also affect the efficiency of the system.

Summary: Here is a quick summary of the 3-pass boiler design

The First Pass –Flue gases move from the burner end, along the furnace, to the rear reversal chamber.

The Second Pass –Flue gases move from the rear reversal chamber, along the smoke tubes, to the burner end again.

The Third Pass –Flue gases move from the front reversal chamber, along the second set of smoke tubes, to the smokebox at the rear end.

What are the advantages of using a 3-pass Boiler?

The main reason for developing a 3-pass boiler was to maximize heat transfer. Within the same volume of the boiler, we get a larger surface in contact with the water, transferring heat. In this way, the boiler efficiency increases significantly. Boilers are lined with refractory to prevent the metal from overheating. However, due to the 3-pass designs, the flue gases do not need to be at extremely high temperatures to produce steam. Hence, the refractory requirements decrease to some extent. 3-pass water tube boilers are also available in the market. The design is almost similar to these boilers, but the tubes carry water instead of flue gases.

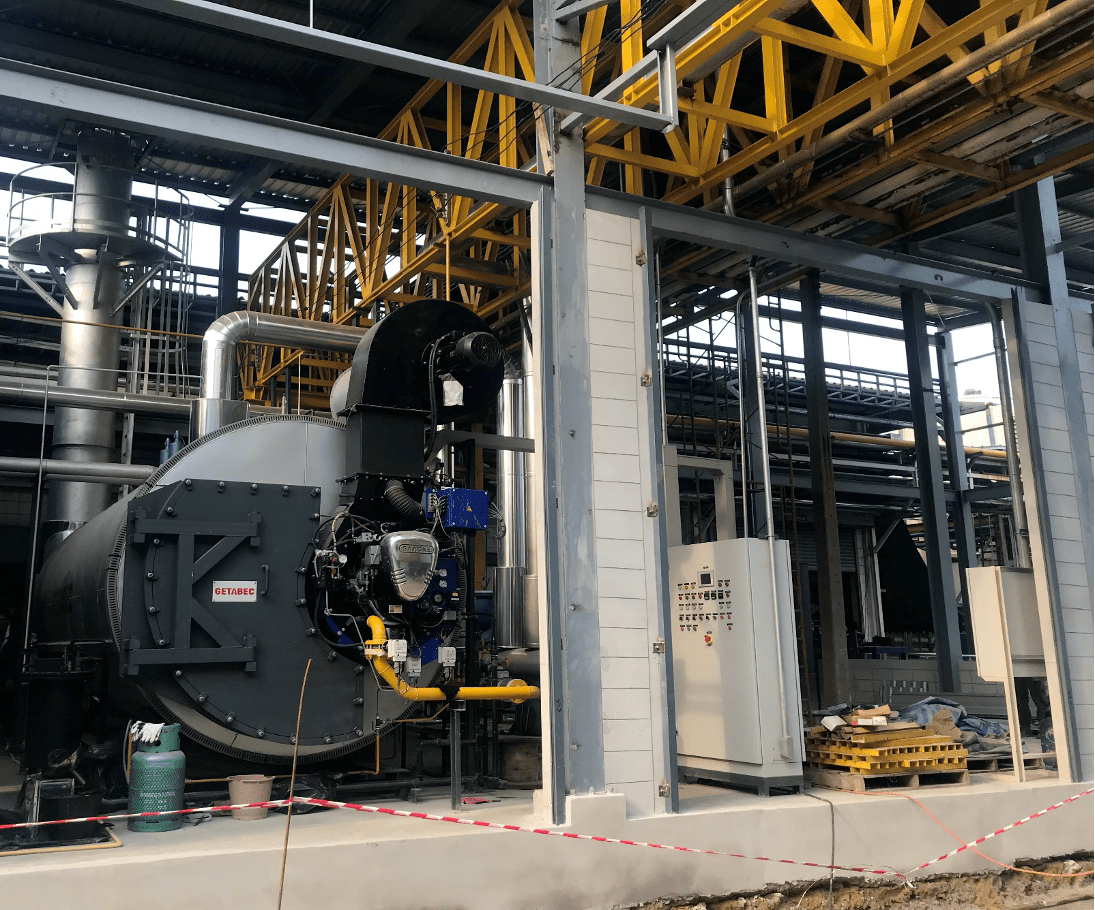

GETABEC’s 3-Pass Boiler Systems:

If you are looking for efficient and customizable boiler solutions, GETABEC can help you out. We are authorized boiler producers with a highly trained service staff. All our designs have the necessary certification (more information here) and are made to minimize fuel consumption, ensure safety and maximize efficiency.

So, call GETABEC today and get a quote!